Pad printing

When pad printing or transfer printing, customised and detailed motifs are printed very precisely on various surfaces. Our prints appear razor-sharp, even under a magnifying glass. We can print your product with four different colours in a single pass in our four-colour pad printing system. In 2022, the system was also equipped with a swivel mount. Since then, we have therefore also been able to process cylindrical parts, as the parts to be printed can each be rotated by 180° and can therefore be printed all the way round.

Efficient printing of all materials

Thanks to our fully automatic four-colour printing machine, large-scale printing production can be achieved within a short period of time.

Top quality, even on curves

We also print objects with curves. The print is still razor-sharp in this process and therefore enhances your product.

We mix up your desired colour

We have an in-house mixing system with the most common colours (RAL, NCS, Pantone) and can mix up your desired colour in an extremely wide range of qualities.

Various gloss levels

We would be happy to mix up all of our paints for you in the levels gloss, matt, high gloss, flat matt, silk gloss or silk matt.

Combination of pad printing and protective varnish

In order to optimally protect the printing on your product, we are more than happy to coat it with one of our high-quality protective varnishes.

Different batch sizes

We can take on any type of task – from individual products to large-scale series solutions.

High-quality surface finishing thanks to pad printing

We print objects up to 80x80 mm using pad printing.

Watches and packaging

Dials

Analogue speedometer displays

Cufflinks

Medical devices

Electronic device housings

USB sticks

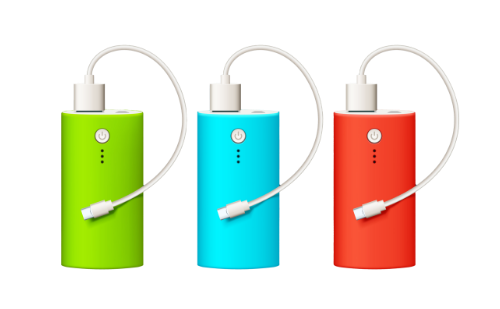

Chargers

Screen printing

Larger motifs can be printed precisely on flat surfaces using the screen printing process. The colour and colour transparency can be varied specifically depending on the requirements. Since the coating applied is only a few micrometres thick, the paint dries very quickly and your product can be further processed in no time.

Customised colour design

We design your product precisely according to your requirements. You choose the colour tone, colour quality, gloss level and colour transparency.

Various gloss levels

You also have the choice between the levels gloss, matt, high gloss, flat matt, silk gloss or silk matt when using screen printing.

Fast processing

Since we mix our colours in-house, we ensure that your task is completed quickly.

Combination of screen printing and protective varnish

We recommend coating your product with one of our high-quality protective varnishes to optimally protect the paint

Customised batch sizes

We produce both individual products as well as large-scale series solutions for you.

High-quality surface finishing thanks to screen printing

We print objects up to 350x150 mm using screen printing.

Function buttons

Machine housings

We look forward to your request

Get in touch with us